Advanced Fasteners and Machining Techniques for Customized Manufacturing

Advanced Fasteners and Machining Techniques for Customized Manufacturing

Blog Article

Navigating the Globe of Fasteners and Machining: Strategies for Accuracy and Speed

In the complex world of fasteners and machining, the mission for accuracy and speed is a perpetual obstacle that demands careful attention to detail and critical planning. From comprehending the varied selection of fastener kinds to choosing ideal products that can endure extensive needs, each action in the process plays a crucial function in attaining the preferred end result. Accuracy machining methods additionally boost the complexity of this craft, requiring a fragile equilibrium between technological experience and ingenious approaches. As we dive into the techniques that can improve both rate and effectiveness in this domain, the interplay in between quality assurance actions and functional quality becomes a critical focal factor.

Understanding Bolt Types

When choosing bolts for a project, comprehending the numerous types offered is crucial for making sure optimal performance and dependability. Screws are used with nuts to hold products together, while screws are functional fasteners that can be used with or without a nut, depending on the application. Washing machines are essential for distributing the tons of the bolt and preventing damages to the material being fastened.

Choosing the Right Products

Recognizing the importance of choosing the appropriate materials is critical in making certain the optimum performance and dependability of the selected bolt kinds reviewed formerly. When it comes to bolts and machining applications, the material selection plays a crucial role in identifying the general stamina, toughness, deterioration resistance, and compatibility with the desired setting. Various products supply differing homes that can dramatically influence the efficiency of the bolts.

Typical products utilized for fasteners include steel, stainless steel, aluminum, brass, and titanium, each having its distinct staminas and weak points. Steel is renowned for its high strength and longevity, making it appropriate for a vast array of applications. Stainless-steel provides exceptional deterioration resistance, suitable for environments vulnerable to moisture and chemicals. Aluminum is corrosion-resistant and lightweight, making it appropriate for applications where weight reduction is critical. Brass is typically picked for its aesthetic charm and excellent conductivity. Titanium is recognized for its exceptional strength-to-weight proportion, making it perfect for high-performance applications. Selecting the ideal material entails taking into consideration aspects such as strength requirements, ecological conditions, and budget plan restraints to ensure the preferred efficiency and longevity of the bolts.

Accuracy Machining Techniques

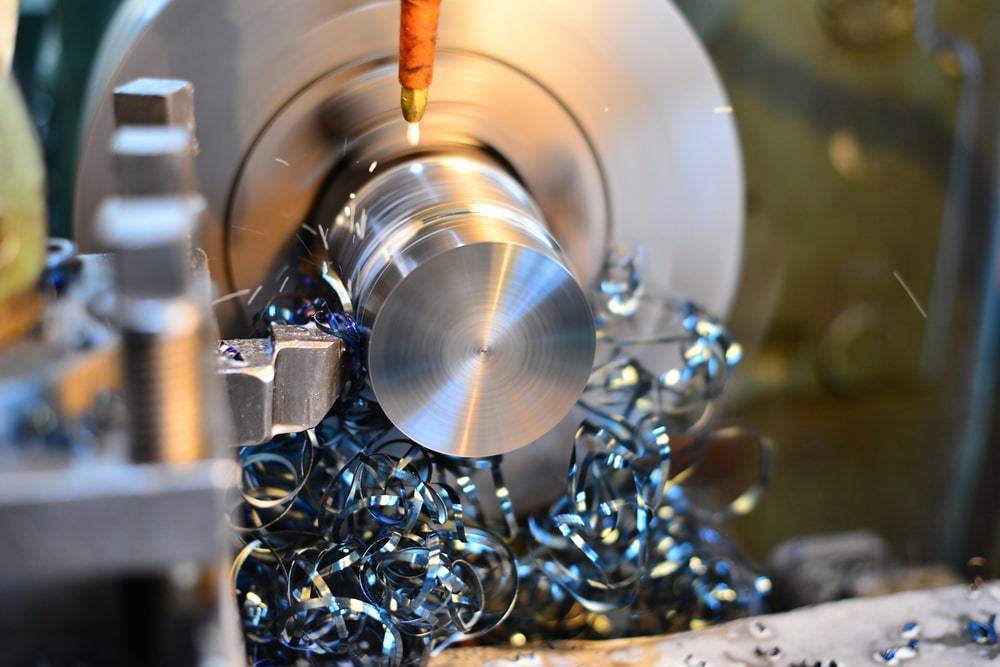

Along with look what i found CNC machining, other accuracy methods like grinding, turning, milling, and drilling play important duties in bolt production. Grinding aids attain fine surface area coatings and limited dimensional tolerances, while transforming is often utilized to produce cylindrical parts with exact sizes. Milling and drilling operations are important for forming and producing openings in fasteners, ensuring they fulfill specific specifications and feature correctly.

Enhancing Speed and Effectiveness

To maximize fastener production procedures, it is important to improve operations and execute efficient strategies that complement accuracy machining methods. Automated systems can take care of repeated tasks with accuracy and rate, permitting employees to focus on even more complex and value-added tasks. By integrating these techniques, makers can attain an equilibrium between rate and accuracy, ultimately improving their competitive side in the bolt industry.

High Quality Control Actions

Implementing rigorous top quality control measures is vital in guaranteeing the dependability and uniformity of fastener products in the production process. Fasteners and Machining. Quality control actions incorporate numerous phases, starting from the choice of raw materials to the last examination of the ended up fasteners. This includes assessing variables such as product structure, longevity, and stamina to ensure that the fasteners satisfy sector requirements.

Regular calibration of devices and machinery is imperative to preserve consistency in production and guarantee that fasteners fulfill the required tolerances. Implementing stringent methods for identifying and addressing problems or non-conformities is vital in preventing substandard products from entering the market. By establishing a detailed top quality control structure, suppliers can copyright the credibility of important link their brand name and supply bolts that meet the highest criteria of performance and longevity.

Verdict

In the detailed world of bolts and machining, the mission for accuracy and speed is a perpetual difficulty that demands thorough focus to detail and critical preparation. When it look at this now comes to fasteners and machining applications, the product option plays an essential role in identifying the general toughness, resilience, rust resistance, and compatibility with the intended atmosphere. Precision machining includes different innovative approaches that make certain the limited resistances and specifications needed for bolts.In addition to CNC machining, other accuracy strategies like grinding, transforming, milling, and drilling play crucial functions in fastener manufacturing.To enhance fastener manufacturing procedures, it is crucial to enhance procedures and execute effective techniques that enhance accuracy machining techniques.

Report this page